How To Build A Concrete Washout Reclaimer

April 28, 2013Not all Ready-mix producers need a 100% close loop concrete reclaimer for their plant site. Some producers can get by with a basic Concrete Washout Reclaimer if their haul-off costs are cost effective. A Concrete Washout Reclaimer consists of a Washout Pit with 3 bays and couple of three sided drying bays with a sand berm on the open side. The floor of the washout bay is concrete with a 4 degree slope towards the sand berm. Mixer trucks back up to the sand berm and discharge their washout water into the bay. Gravity takes the solids to the bottom, while the water leaches through the sand berm and into the nearby pit. When the washout bay has filled up with solids, the mixer trucks will move to a second bay and repeat the process. Typically producers will alternate between bays weekly. This allows the full bay to de-water, before the loader operator scoops up the waste material + sand filter and stock piles onto a nearby concrete pad before hauling off to a concrete recycler.

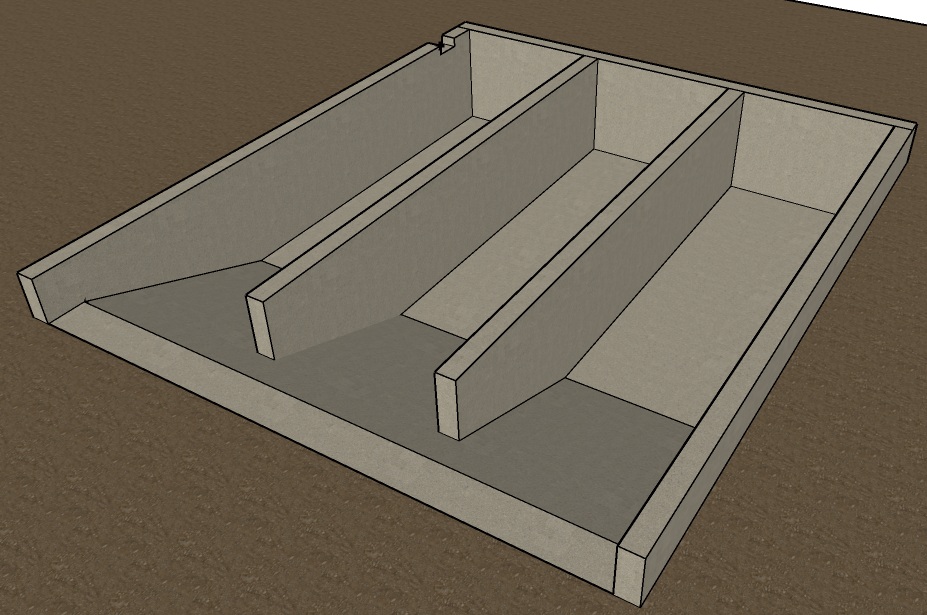

Typical 3-Bay Washout Pit System

Washout area with sand berm.

The collected water in the pit is pumped into a above ground plastic tank for storage and re-use. The recycled water can be used as batch plant and mixer truck washout water. The use of a automatic pH balance system will maintain the recycled water at a pre-determined pH level.