Monitoring the "heart" of every Wet Plant. Pinion Gears.

October 24, 2023A consistent maintenance and service program, is the foundation to every successful concrete batch plant operation.

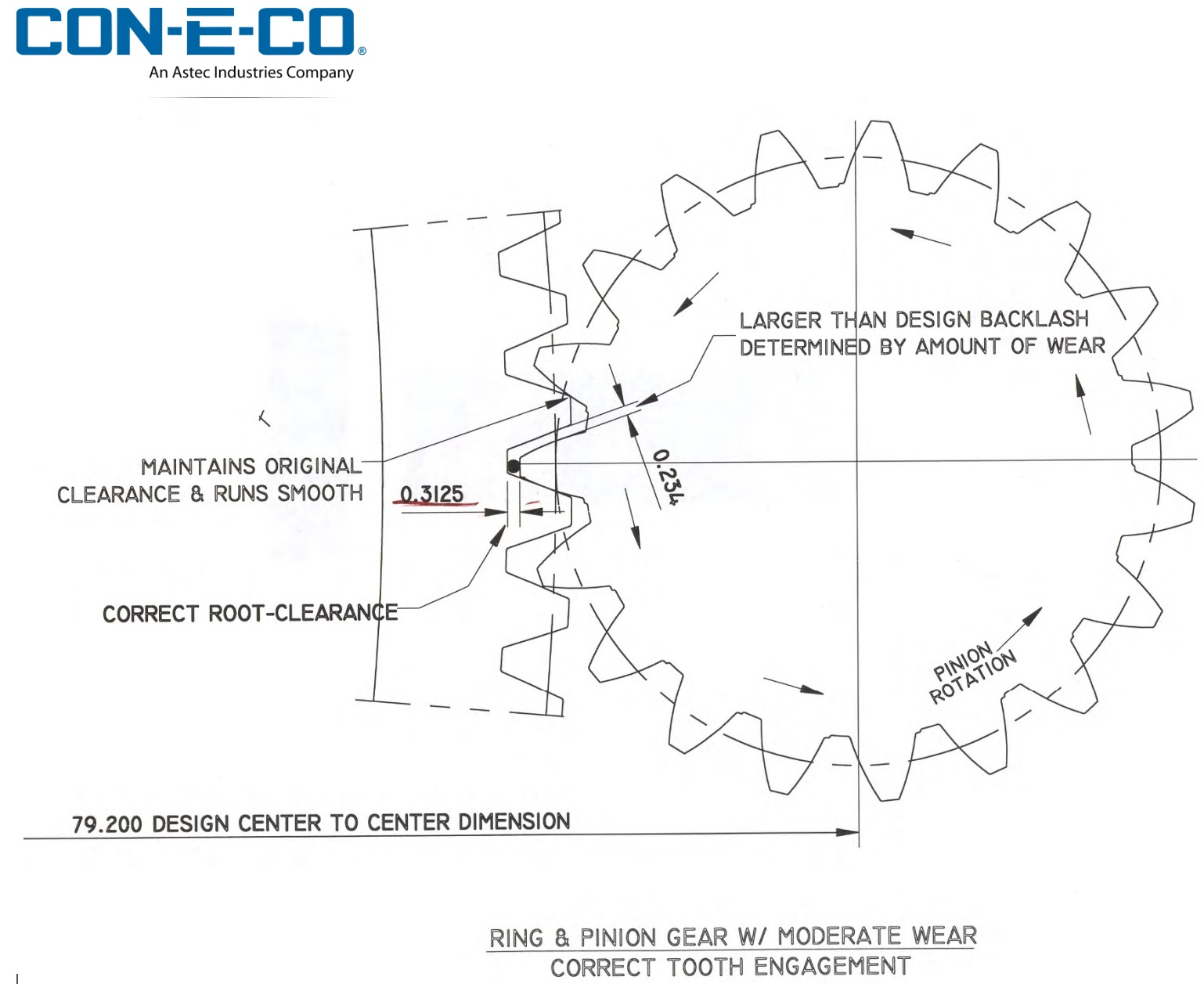

In particular monitoring the wear on a Tilt Mixer’s Drive System will extend the life of a mixer drum and reduce the cost of producing concrete with a Wet Plant. The tolerance of the Pinion gear to the Bull ring is the epicenter of the energy to produce wet concrete. This tolerance is documented by the CON-E-CO factory for new mixers and can be easily checked by the operator in the field. Alignment of Pinion Gears should be checked after changing or adjusting support rollers or if the mixer drive assembly has been moved. The picture below shows the tolerances to confirm based on the factory settings. Before making any adjustments please consult with the CON-E-CO service department.

Service - Mixer Drive Assemblies

Continuously · Monitor for unusual or irregular sounds and vibration while mixer is operating · Monitor that pinion gear has been oiled sufficiently.

Daily · Inspect drive assembly for oil leaks.

Weekly · Check and document temperature of gear reducer · Check the motor mount assembly has not moved.

Monthly · Check oil level in gear reducers · Inspect condition of pinion gears · Inspect Para-Flex coupler flange bolts and bushing bolts and torque as needed · Inspect motor mounting bolts and torque as needed · Inspect reducer mounting bolts and torque as needed · Inspect pinion gear mounting bolts and verify safety wire is in place · Inspect for sound connections on mixer motor junction boxes and motor wiring.

Semi-Annually · Change oil in gear reducers · Remove pinion gear keeper plates and inspect reducer output shaft and keyway · Check and document pinion gear root clearance to ring gear at High Spot on each side.