How to Build a Basic Concrete Reclaim System

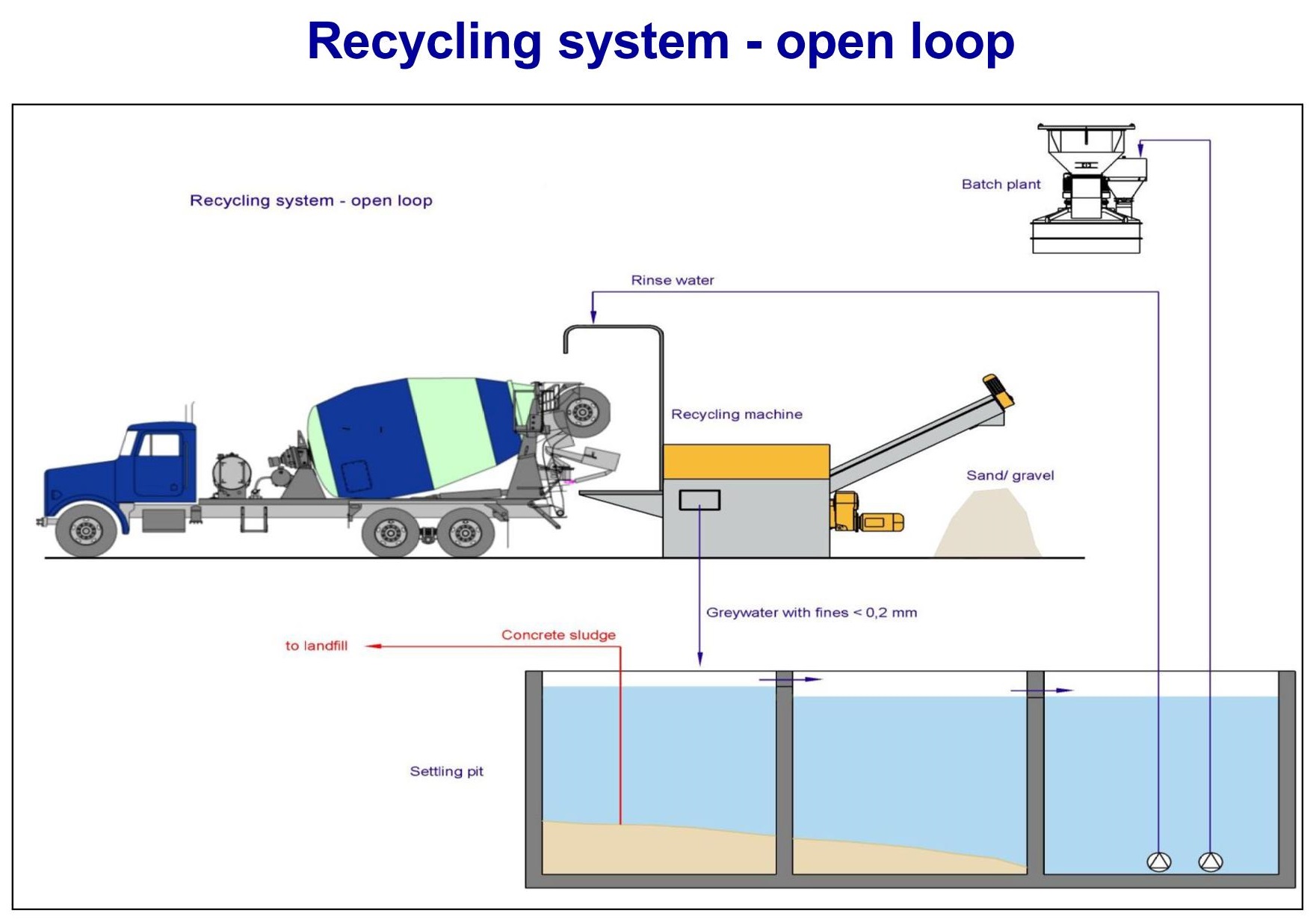

April 22, 2019Concrete reclaimers can come in many different configurations depending on the need. Sometimes a simpler approach will create the best reclaimer for a concrete producer. A basic reclaimer with 3 settling ponds can provide enough reclamation to meet most plant washout needs. Concrete reclaimers are the only piece of equipment that pulls apart fresh concrete into its individual components for re-use or disposal. Working backwards from largest materials to smallest, a BIBKO 2000 (25 yds/hour) or a BIBKO 4000 (40 yds/hour) can remove aggregate and sand from the cement slurry water. The patent design of a BIBKO reclaimer controls the driver feed rate of return concrete into a wet process that uses gravity and physics to separate, wash and dewater the reclaim aggregates and sand. By using existing slurry water for the process, the operator is not adding to the water management problem. As the aggregate is discharged into a stock pile or optional screen for separating, the slurry water is skimmed over a weir and discharged into a customer concrete pit.

Using gravity to filter slurry water - Concrete pits usually incorporate 3 individual pits that allow the sediment of the wash water in pit #1 to fall to the bottom while the clarified water flows to pit #2 to repeat the same process before finally flowing to pit #3 as clarified water. From pit #3 the water can be pumped to the batch plant using a 450 GPM submersible water pump for re-use into fresh concrete. The loader operator can muck out the pits and discharge into concrete bunkers with a sand berm to act as a water filter. Once dried (25% moisture) this material waste can be hauled off to the quarry for recycle.